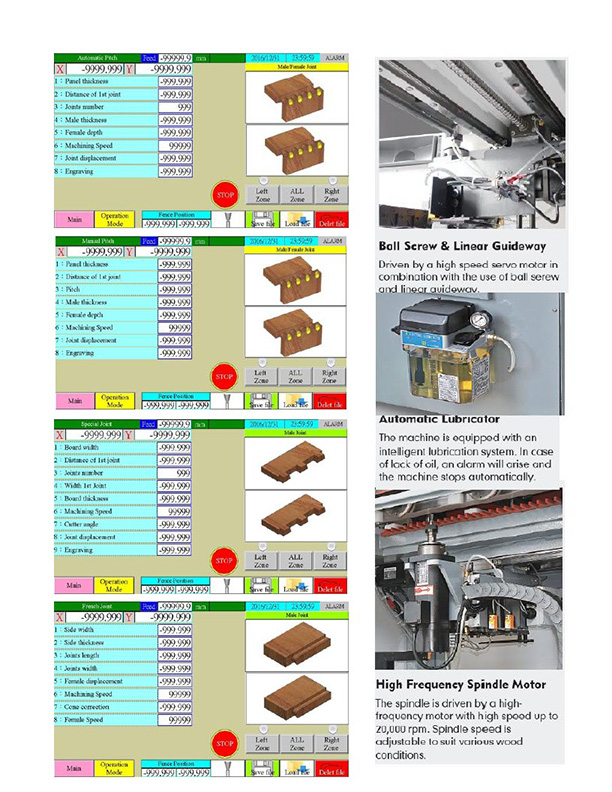

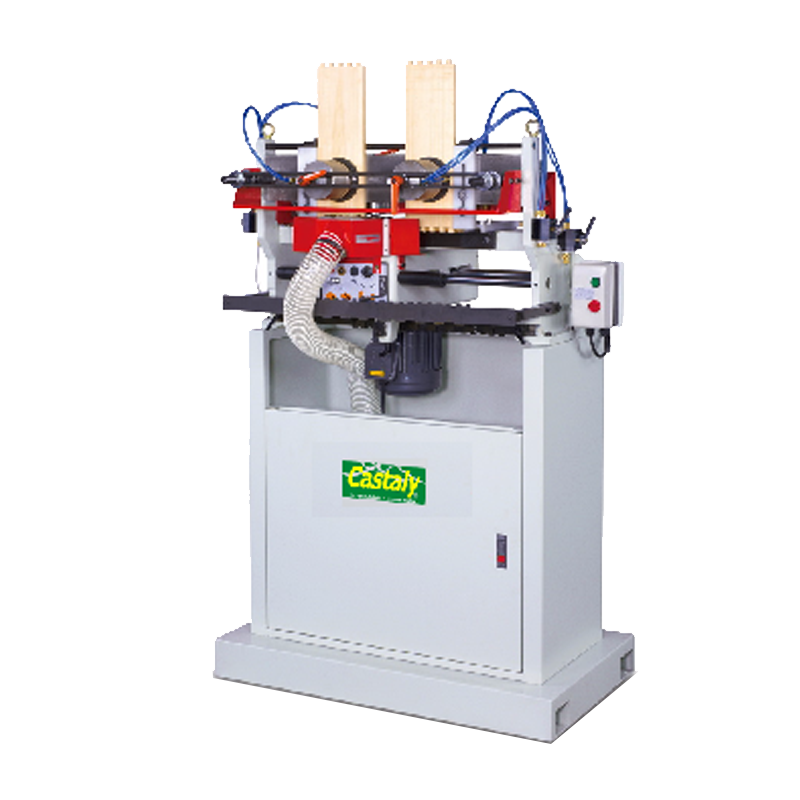

Features:

• Pre-load auto program movements for complete cutting cycle.

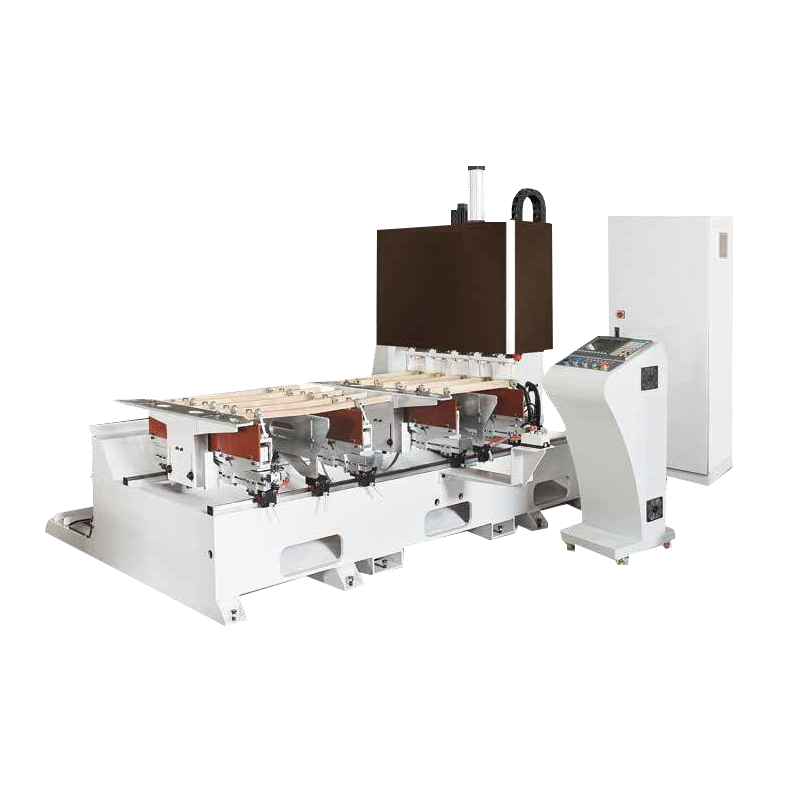

• Operators can choose the models according to demands, able to change or design wood materials variously, set the working speed, sizes of tenons & mortises, intervals by simple human operation interface. The files can be saved for repeat use. Heavy steel frame and

cast-iron table for long-life usage.

• Four large air clamps for making two sets of male and female dovetails at the same time.

• Servo router head travels at precision linear bearing providing smoothness and accuracy.

• Male and female dovetails are produced at the same time for maximum match accuracy.

• Variable cutting speeds for best finish of different materials.

• Easy operation and maintenance.

• Nonstop Working Design: After operators input programs, Controller will separate the working tables into left & right areas. When one area is working, operators can change the materials at the other area. In this way, machines don’t need to stop & increase work efficiency.

• Main Motor: High Frequency. Durable & stable. The rotation speed is up to 20,000 RPM.

• Processor: Quality PLC made by Japan Mitsubishi. All electric equipment conforms to CE standards.

• Debug System: The computer stops automatically under perfect protection upon wrong operation or setting for fear of over stroke. Detailed error messages will be shown for operators to understand & debug.

• Circuit Design: The machine stops automatically under power failure or insufficient air pressure for fear of danger led by clamping cylinder.

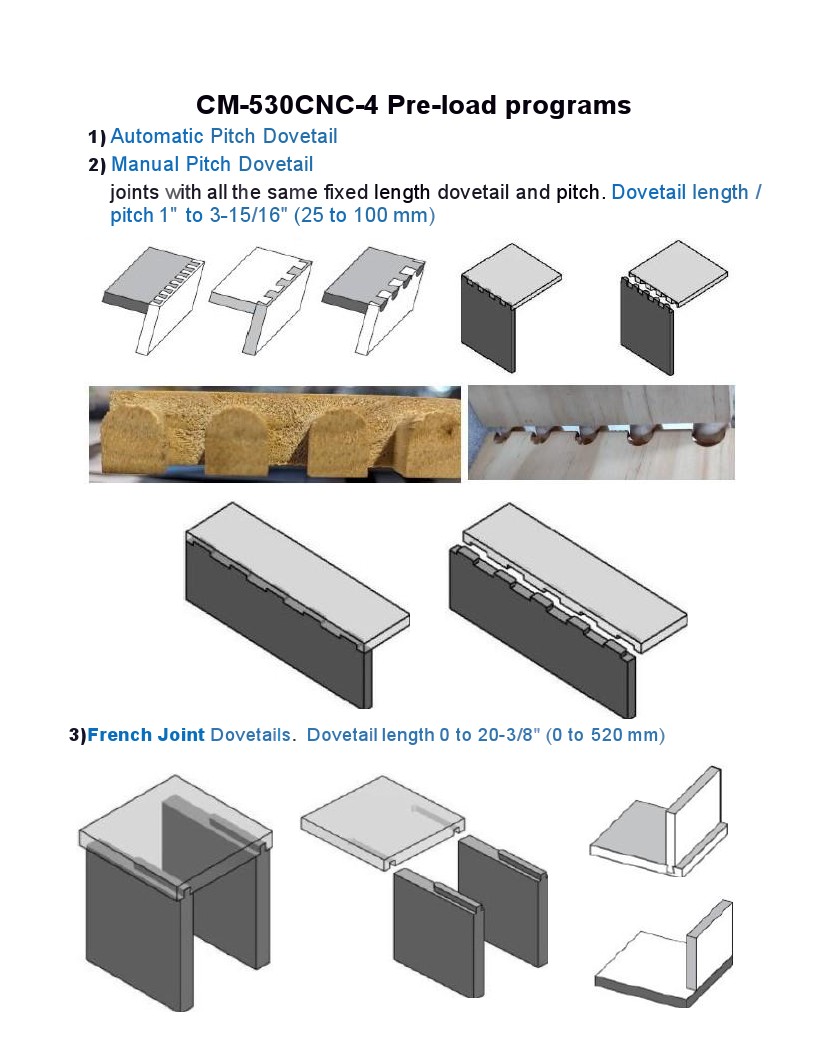

Pre-Load Dovetail's Type Program

1. Automatic Pitch: This program can be used to perform joints with a varying pitch.

After the establishment of the width of the side that has to be machined, the distance

of the first joint and the number of joints, the numerical control determines the pitch

of the joints leaving two with equivalent dimensions on both sides of the piece that

must be machined.

2. Manual Pitch: With this program, it is possible to machine joints with a fixed pitch (e.g. a

pitch of 25-30-40mm etc.). The width of the drawer side to be machined, the distance of the first joint and the joints pitch must be defined; then the numerical control will allow for the machining of the exact number of joints that fit to the workpiece's length.

3. Special Joint With this program, it is possible to machine a joint a rectangular pass-through

male piece and a parallel joint

4. French Joint With this program, it is possible to machine mortise joints on the X axis.

Specification:

| SPECIFICATIONS | |

| Working Width | 1" ~ 20-7/8" |

| Working Thickness | 3/8" ~ 1" |

| Main Spindle Motor | 2 HP |

| Max. Spindle Cutting Speed | 20,000 RPM |

| X, Y Axis Servo Motor | 1000 kw x 2 |

| Controller | PLC |

| Dust Hood | 4" x 3 |

| Machine Size (L x W X H) | 59" x 33" x 51" |

| N.W. | 1450 LBS |

Related Products

-

1 Bit 36" Auto Dovetail Machine

CM-A36 $19,990.00 -

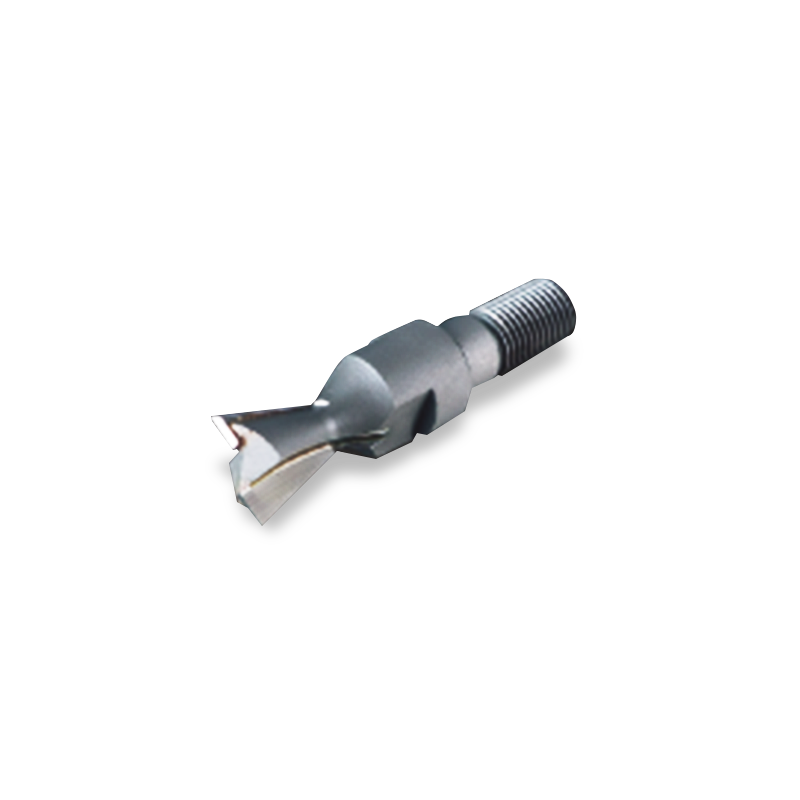

Dovetail Cutter Bit for CM-16AT, CM-24AT

CM-24BD $49.00 -

28” Manual Dovetail Machine

CM-28M $3,690.00 -

1 Bit 19" Curve / Straight Auto Dovetail Machine

CM-C19B $17,900.00 -

CNC 5 Spindles Machine Center One 110” Zone or Two 55” Zones

CNC-105-DU $99,900.00 -

59” Manual Dovetail Machine

CM-59M $4,790.00 -

1 Bit 19" Auto Dovetail Machine

CM-A19 $11,690.00 -

16 Bits Auto Dovetail (Left & Right Cutters) Machine

CM-16AT $27,990.00